If you would like to arrange to send samples to us for rheological characterisation, or indeed characterise other material properties, please feel welcome to contact us. Whether you are working with oils, emulsions, suspensions, polymer solutions or gels, we have a number of accessories for working with complex fluids, and decades of experience generating reliable data accurately and quickly. Most materials will decrease in viscosity as an increase in temperature is applied, we can provide data tracking viscosity as a function of temperature so you can optimise your processes.

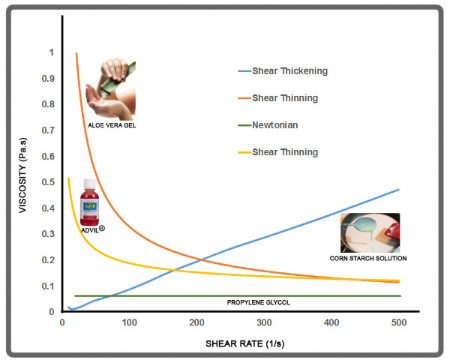

This ‘zero-shear’ viscosity or ‘cut-off’ viscosity can be useful for simplifying simulations below a critical value. For some materials such as gels and emulsions, a plateau viscosity can be observed below a critical stress. Our lab is equipped with state-of-the-art rheometers capable of measuring viscosity under very low stress conditions. For non-Newtonian materials, we can provide Power-law model fits including ‘k’ and ‘n’ values (also known as the ‘viscosity coefficient’ and ‘power number’ respectively) or yield stress values for Herschel-Bulkley models. We provide viscosity measurements for both Newtonian and non-Newtonian materials and can deliver data in whatever format is most useful to you. The algorithms used to predict fluid behaviour in specific designs need real world data to be accurate, viscosity being one of the most important. Whether you are looking to model flow through a heat exchanger, pump or drug delivery meducak device, within a mixing vessel or even blood pumping within the chambers of the heart, we have spent decades working with a variety of different material types and are well equipped to gather accurate viscosity and rheology data fast.Ĭontact our lab to arrange a virtual tour of the lab and discussion of how we can help.Ĭomputational fluid dynamics are vital for accelerating the design and optimisation of fluid processing lines. The Centre for Industrial Rheology also provides several other complimentary materials characterisation services including yield stress measurements, surface tension measurements, viscoelasticity measurements and thermal conductivity and curve fitting to popular models. For example, if you squeeze a tube of toothpaste, how easily does. Our lab is equipped with state-of-the-art rheometers capable of measuring viscosity under very low stress conditions. This information is used for blending oils determining the spray (nozzle) characteristics of oil burners and diesel fuels defining a product's lubricating properties and predicting how a mixture of oils and other products will dry, protect, spread, etc. It uses an electronic motor to provide drilling fluid engineers with an extremely accurate and versatile tool.įield-proven 2-speed models are also available.We provide comprehensive viscosity measurements for CFD modelling as a service for anybody using packages such as Fluent, Star-CCM+, SimScale, COMSOL, Autodesk and more. Viscosity is the measure of how resistant a material is to motion when you apply force to it. Viscosity is a measure of a liquid's flow properties. The Model 800 Viscometer is also suitable for both field and laboratory use. A waterproof case on wheels makes the unit completely portable. Viscosity Loss With each of the shear degradation methods, the viscosity is analyzed before and after the permanent shearing of the fluid. The rugged viscometer is suitable for both field and laboratory use. Savant offers CEC L-45-A-99 Modified for KRL testing.

You can even store your data as a text file or spreadsheet for easy access and reporting capabilities. Using the exclusive ORCADA ® software, a computer novice can operate the viscometer, and yet the system is versatile enough for advanced research and demanding test parameters. You can even clean the cup and change fluids without disassembling the unit.

This fully-automated system accurately determines the flow characteristics of completion fluids and drilling fluids in terms of shear stress, shear rate, time, and temperature at pressure up to 2500 PSI. Mud engineers will appreciate the push button calibration, not to mention getting standard API tests with one command.įor enhanced data collection, OFITE offers the Model 1100 High Temperature Viscometer. Its simplicity makes it ideally suited for the field, yet with the addition of a computer can perform as well as any lab machine available today. OFITE's Model 900 Viscometer is extremely versatile. OFITE offers a complete line of concentric-cylinder, couette viscometers for use in analyzing drilling fluids and completion fluids. Viscometers, sometimes referred to as rheometers, are used to measure fluid properties. Rheology is the study of the behavior of fluids.

0 kommentar(er)

0 kommentar(er)